Brief Introduction of Plastic Injection

Introduction of Plastic Injection

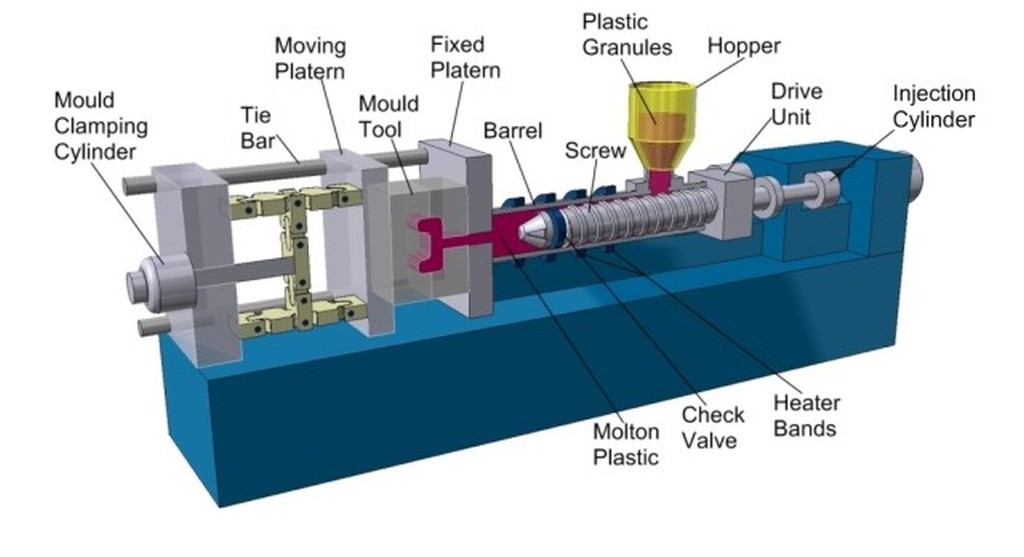

Plastic Injection machines uses a huge screw to drive molten raw plastic material into the mold gate with a high pressure.

The high pressure is needed to ensure that the plastic resin fills in each empty cavity. When the molten plastic parts are cool down via cooling water, the mold platen will open, and the part is ejected or we can also call the parts fallen down from the mold.

Designing an injection molding is complicated, and the cost of the molds themselves are expensive. However, the unit price will be lower once you do mass production for large volume of the parts.

You don’t need to understand every technical detail of plastic injection process. Our engineering tam in Unison Tek will provide you our excellent engineering knowledge. for your reference en.wikipedia.org/wiki/Injection_moulding

How the Plastic Injection Process Works

-

Plastic pellets (usually thermoplastics like ABS, PP, or PC) are fed into a hopper.

-

The material is heated and melted inside a heated barrel.

-

A screw or plunger pushes the molten plastic into a steel mold cavity under high pressure.

-

The plastic cools and solidifies inside the mold, taking the shape of the cavity.

-

The mold opens and ejects the finished part.

-

The cycle repeats for high-volume production.

Advantages of Plastic Injection Molding

- High Efficiency: Fast cycle times make it ideal for large-scale production.

- Consistency and Precision: Produces parts with tight tolerances and repeatability.

- Design Flexibility: Supports complex geometries, undercuts, and thin walls.

- Low Waste: Excess material can often be recycled or reused.

- Cost-Effective for High Volumes: Lower unit cost at scale.

CNC ISO 9001:2015 Certified Machine Manufacturer in Taiwan for OEM/ODM/Customized machined products for 36 years in Taiwan.

Please visit CNC Turning Parts, Machined Parts, Stamping Parts,Technical Data for your reference and Quality Inspection to get more information about us, if you have any questions, please e-mail to Harry Yen hyen@unisontek.com.tw

We will reply to you in 24 hours, and we're willing to offer you a nice quote, and our engineering team would also provide you a professional mechanical advice for you.

People in Unison Tek are looking forward to your good news and invite you to visit our cnc machining factory in Taiwan. Please watch our company channel on YouTube Link and introductio Link.

2025 Copyright of UNISON TEK CO., LTD. © All Rights Reserved.